Smart Manufacturing

Smart Manufacturing

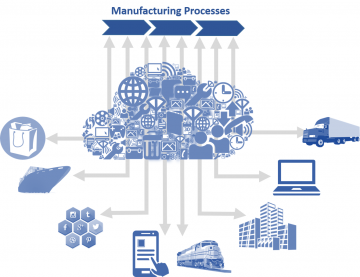

Smart Manufacturing also known as “Industrie 4.0” is based on a combination of digital and physical systems that blend communications, IT, data, device, equipment and people. These systems transform traditional plants into smart factories through highly intelligent, connected systems that create a fully digital supply chain. The value of a digital supply chain lies in its volume of rich, correlated data, which allows you to recognize and optimally respond to events in real-time, and provides a treasure trove of data to be mined and analysed to support continuous improvement efforts. And the digital supply chain is more agile than traditional supply chains, able to keep up with the pace of operational change in today’s manufacturing environment.

Since year 2001, SWIFT is continuing bringing technology solutions to the manufacturing sector. With thousands of solutions deployed to Oils & Grains, Oil & Gas, Food & Beverage, Automotive, Specialty Chemical, and other manufacturing verticals, we have a deep understanding of manufacturing operations and related business processes.

With our history in developing MES and process control systems, we have a deep understanding of ERP, PLM, MES, and other shop floor systems you need to connect to in order to achieve the vision of smart, connected operations. Our agile development methodologies supporting rapid prototyping and iterative development, resulting in shorter time to benefit. Our automation and controls groups has years of experience connecting to shop floor equipment and devices, a key element of IoT.

In short, SWIFT has the experience and knowledge required to bring the value of IoT to the manufacturing sector.